Supported engines: Single-Cylinder and Twin-Cylinder engines

Introduction:

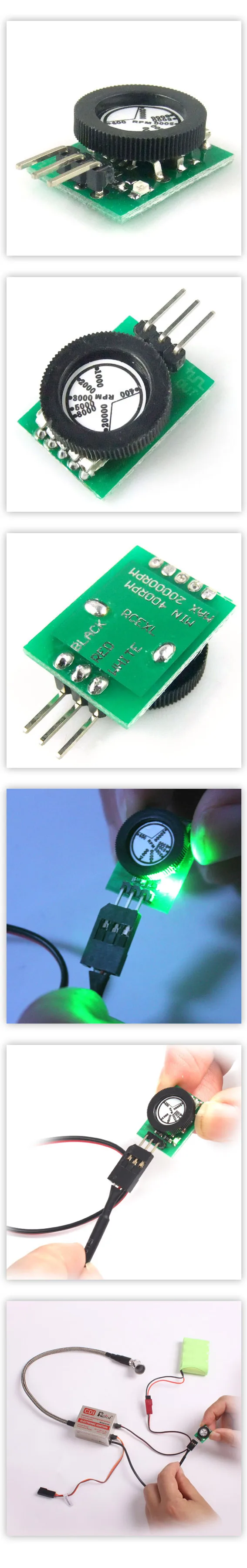

This is timing and testing kit for RC Gas/Petrol engines using CDI ignition.

This kit, will allow you to check ignition working conditions without the need to start the engine.

Analog engine speed in between the 400RPM-20000RPM, this kit can be used to check radio interferences, and the radio range check.

Full instructions supplied.

WARNING

This unit will fire the spark plug, and if still fitted to the engine, any fuel vapor still inside the engine may ignite and rotate the propeller and/or cause flame/heat from the exhaust.

DO NOT TOUCH SPARK PLUG

When this is running or you will receive an electric shock!

1. Turn ignition OFF

2. Ensure spark plug is properly seated into ignition cap. Spark plug must be used or damage to ignition module is possible.

3. Use dial on tester to set desired RPM – this will simulate a hall sensor being triggered and will fire the ignition/Spark plug at this RPM setting.

4. Disconnect hall sensor from ignition and connect tester with correct polarity to the ignition sensor lead coming out of the CDI

See photo below for correct connection – note wire colors.

5. Turn on ignition power. The LED on the tester will light if connected correctly, and the spark plug will start firing at the set RPM. You can adjust the dial to increase/decrease the RPM. If LED will not light the tester may be faulty or the sensor/wiring is not compatible.

6. If plug is firing you are now simulating a running engine/ignition and can complete range tests for ignition noise etc without actually running the engine. If the spark plug does not fire, check above connections to tester first. Otherwise

• Check ignition battery is good. Do not use an old pack

• Check all wiring and leads are connected correctly and not damaged.

• Check/Replace spark plug

• If your ignition still does not fire you may have a faulty ignition or tester

• If Ignition fires OK with tester, but not when connected to sensor then your hall/pickup sensor is likely to be faulty or too far from magnet or incorrect orientation to magnet (flip sensor 180 degrees to test)

7. If ignition runs OK at low RPM, but breaks down at higher RPM try another battery first and check wiring to ignition unit (try battery direct to ignition – bypass switch etc)

This can also be caused by short in plug cap/s or faulty ignition module

8. When finished testing turn off ignition power. Disconnect tester and reconnect ignition module to sensor.